装车鹤管英语(装车鹤管设备)

Introduction to Loading Arm Systems: Enhancing Efficiency in Material Handling

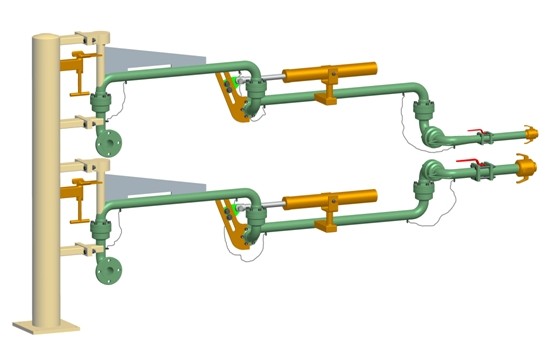

Loading arms, often referred to as "鹤管" in Chinese, are critical pieces of equipment used for transferring liquids and gases between pipelines and storage tanks, vessels, or other containers. These versatile devices are designed to improve safety, efficiency, and flexibility in various industries, such as oil and gas, chemicals, and logistics. By understanding the functionality and benefits of loading arms, companies can optimize their operations and reduce the risks associated with manual handling.

What is a Loading Arm?

A loading arm is a mechanical device consisting of several interconnected arms that can extend, retract, and rotate, facilitating the transfer of bulk liquids or gases. Unlike traditional hoses, loading arms are designed to provide a safer, more controlled method of fluid transfer. They are engineered to minimize the risk of spills, leaks, and accidents, while also allowing for quick and easy connection and disconnection from the receiving vessel or tank.

Loading arms can handle a wide range of materials, including hazardous liquids like chemicals, oils, and gases, making them a valuable asset in industries that deal with high-risk substances. These arms are typically mounted on a fixed platform or truck, ensuring the fluid transfer process is both secure and efficient.

Types of Loading Arms and Their Applications

There are several types of loading arms, each designed to meet the specific needs of different industries:

1. Fixed Loading Arms: These are installed on stationary platforms or structures, providing a reliable and stable solution for routine transfers.

2. Swivel Loading Arms: These arms allow for increased flexibility by rotating to connect with different tanks or vessels.

3. Telescoping Loading Arms: Designed for applications requiring varying lengths, these arms can extend and retract to accommodate different sized containers.

4. Multifunctional Loading Arms: These versatile systems can handle both liquid and vapor transfer, making them ideal for industries dealing with various substances.

Each type has its unique advantages, and selecting the right one depends on the specific transfer requirements and the materials being handled.

Key Benefits of Loading Arms

Using loading arms offers several key benefits, including:

- Safety: Loading arms significantly reduce the risk of spills, leaks, and accidents by providing a controlled and secure connection between the container and the pipeline.

- Efficiency: Loading arms streamline the transfer process, reducing downtime and labor costs associated with manual handling.

- Durability: Constructed from high-quality materials like stainless steel, loading arms are built to withstand harsh environments and extend the life of the equipment.

- Cost-Effective: Although the initial investment in loading arms can be higher compared to traditional hoses, their durability and efficiency result in long-term savings by reducing maintenance costs and improving throughput.

Maintenance and Safety Considerations

To ensure the long-lasting performance of loading arms, regular maintenance and safety checks are essential. Proper lubrication, inspection for wear and tear, and ensuring all seals and connections are intact can prevent costly repairs and downtime. Additionally, it is crucial to train operators on the correct use of loading arms to prevent accidents and ensure compliance with safety regulations.

Conclusion: The Importance of Loading Arms in Modern Industry

In conclusion, loading arms are indispensable tools in various industries, offering a safer, more efficient, and cost-effective solution for handling bulk liquids and gases. Their versatility, coupled with their safety features, makes them essential in sectors dealing with hazardous materials. By understanding the types, benefits, and maintenance needs of loading arms, companies can improve operational efficiency and mitigate risks. The adoption of loading arms is a significant step toward modernizing material handling processes and ensuring long-term sustainability in industrial operations.

同类文章排行

- 吉林辽源化工厂定制采购的一批AL2543型汽车底部密闭装卸鹤

- 辽宁铁岭客户定制采购的一批AL2503汽车底部卸车鹤管(氟利

- 陕西渭南定制采购的一批 AL2543汽车底部密闭装卸甲醇鹤管

- 安徽淮南化工厂定制采购的一批AL2543型汽车底部密闭装卸鹤

- 陕西运城客户定制采购的一批AL1403顶部装车鹤管(浓硫酸鹤

- 株洲乙醇鹤管厂家揭秘:行业前景与选择秘诀

- 江西新余客户定制采购的一批AL2503汽车底部卸车鹤管(液氩

- 河南商用鹤管厂家电话,助您轻松解决高效输送问题

- 上海卸车鹤管厂家:高效、安全的物流解决方案

- 江苏装卸鹤管生产厂家:行业新标杆