装车鹤管英文(装车鹤管设备)

Overview of Loading Arm Systems

Loading arms, also known as loading hoses or articulated arms, are crucial components used in industries such as petroleum, chemicals, and liquefied gases for transferring liquids or gases from tankers, ships, or railcars to storage tanks or pipelines. These systems provide a safe, efficient, and flexible solution for the transfer process, ensuring minimal risk of spillage, leakage, or accidents. This article aims to provide a comprehensive overview of loading arms, their components, benefits, and various applications in modern industrial settings.

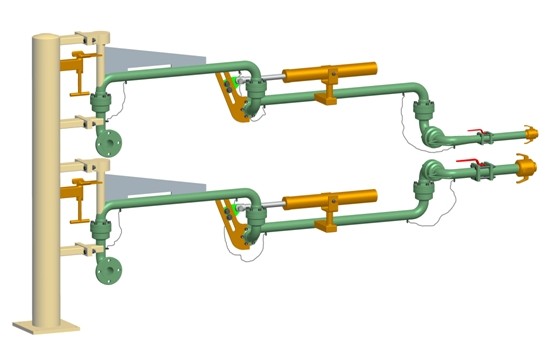

Components of a Loading Arm

A typical loading arm consists of several key components designed for both durability and flexibility. These include the arm tube, swivel joints, counterweight, and support structure. The arm tube is the primary conduit through which the material is transferred, while swivel joints allow for movement and flexibility, enabling the arm to adjust to different positions without kinking. The counterweight ensures proper balance, and the support structure holds the arm in place during operations. These parts work in unison to allow for safe and effective loading and unloading processes.

Advantages of Using Loading Arms

The use of loading arms offers a variety of benefits, making them a preferred choice for many industries. One of the key advantages is safety; loading arms reduce the risks of spills and leaks, which is crucial when dealing with hazardous or volatile liquids. They also improve operational efficiency by allowing for faster and more controlled transfer of materials. Furthermore, loading arms are designed for ease of use, reducing manual labor and enhancing the overall productivity of the operation.

Types of Loading Arms

There are different types of loading arms, each suited for specific applications. Some of the most common types include single and double articulated loading arms, top or bottom loading arms, and LNG (Liquefied Natural Gas) loading arms. Single articulated loading arms are typically used for transferring liquids between tankers and fixed storage tanks, while double articulated arms are more flexible and can handle larger volumes of liquid with higher safety standards. LNG loading arms are specially designed to handle extremely low temperatures, which are necessary for transferring liquefied natural gas.

Applications of Loading Arms in Industry

Loading arms are widely used in a variety of industries, primarily in oil and gas, chemicals, and food and beverage sectors. In the oil and gas industry, loading arms are used to transfer crude oil, refined products, and LNG from ships to shore facilities. In the chemical industry, they are essential for the safe loading and unloading of hazardous chemicals. Additionally, loading arms play a role in the food and beverage industry, facilitating the transfer of liquids such as milk, juice, and syrup.

Conclusion

In conclusion, loading arms are a vital part of modern industrial operations, offering safety, efficiency, and versatility. They ensure the smooth and secure transfer of various liquids and gases, minimizing risks and optimizing productivity. Whether in the oil, chemical, or food industry, these systems are indispensable for operations requiring high standards of safety and reliability. As industries continue to evolve, the demand for advanced loading arm solutions is expected to grow, driving innovation and improvements in design and functionality.

同类文章排行

- 吉林辽源化工厂定制采购的一批AL2543型汽车底部密闭装卸鹤

- 辽宁铁岭客户定制采购的一批AL2503汽车底部卸车鹤管(氟利

- 陕西渭南定制采购的一批 AL2543汽车底部密闭装卸甲醇鹤管

- 安徽淮南化工厂定制采购的一批AL2543型汽车底部密闭装卸鹤

- 陕西运城客户定制采购的一批AL1403顶部装车鹤管(浓硫酸鹤

- 株洲乙醇鹤管厂家揭秘:行业前景与选择秘诀

- 江西新余客户定制采购的一批AL2503汽车底部卸车鹤管(液氩

- 河南商用鹤管厂家电话,助您轻松解决高效输送问题

- 上海卸车鹤管厂家:高效、安全的物流解决方案

- 江苏装卸鹤管生产厂家:行业新标杆